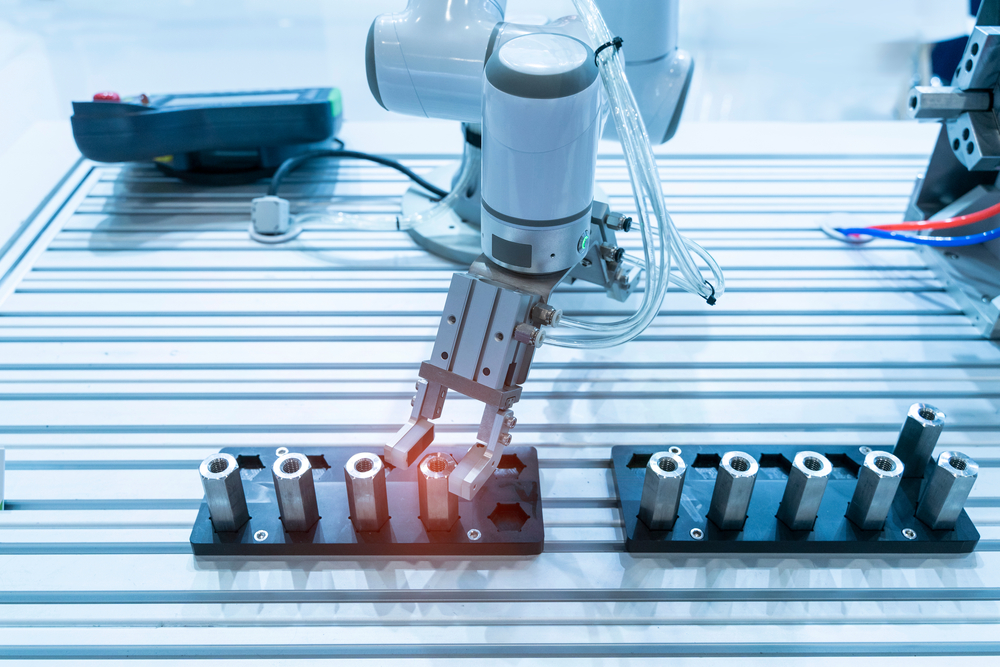

IT and OT integration to improve machine utilization and production efficiency.

The main function of Equipment Automation Integration (EAI) system is to serve as the bridge for communication between equipment and MES. It is divided into Block Control (BC) for automatic assembly line and EAP system for single equipment, depending on the characteristics of the production equipment in the factory.

International communication protocols such as SECS/GEM, OPC/UA, and SCADA are used to transfer data and send commands to control the production equipment, allowing the equipment to perform product processing operations according to pre-planned processes. The system allows for remote control of equipment, release of production parameters, and status monitoring, to achieve automated production of equipment. It can be combined with APC (Advanced Process Control) system to establish communication and feedback between equipment, to promptly resolve product issues. More importantly, it is combined with MCS (Material Control System) and AGV (Automated Guided Vehicle) to achieve the goal of unmanned factories.

Why implement BC/EAP?

Benefits

Digital management

Systematic management of production parameters and process program.

Maintain the quality of mass-production and achieve complete product traceability.

Grasping Prediction

Grasping the operating status and utilization of equipment.

Arranging production and maintenance plans for equipment in advance to improve efficiency.

Accurate information

Automatically transferring real-time production output data. Shortening and optimizing work processes and improving efficiency.

Real time notification

Real-time displaying and returning equipment status and production output data. Setting up monitoring items based on needs to better the functions of alarm management.

Who needs BC/EAP?

Scope of Application

- Assessment of the Manufacturing Industry’s Implementation of Smart Equipment and Production Lines

- By automation to reduce the workforce on production lines

- Equipment capable of handling small quantities of diverse products.

- Needs to cut the cycle time of WIP (Work in process) and improve quality and yield rates

- High-risk manufacturing industries with high-temperature or other hazardous processes

- Highly efficient process flows and fixed routes

Industry

- General manufacturing industry

- Automotive components

- Aerospace components

- Computer, communications, consumer electronics

- Steel industry

- Semiconductors, panels

Best timing to implement BC/EAP

Equipment

When a factory purchases new equipment

Stability

Need to pursue the stable productivity

Solve problems

Analyze the collected production data to solve the problems occurred in the factories

Delivery time

Through automation to shorten the delivery time of purchase orders and raise the order fill rates

Prediction

Integrate the collected production data with operation planning to predict the future operations of a company

【Online Seminar】Introduction to EAP Implementation Framework in PCB Industry

The trend of smart factories is rapidly spreading in the manufacturing industry. While general factories spend a lot of money on equipment automation and data collection, most of the data still requires manual post-processing. This makes it difficult for the MES (Manufacturing Execution System) to fully control machine production and product quality through the EAP (Equipment Automation Program), resulting in a significant setback in smart manufacturing and hindering companies’ progress towards successful transformation. In this seminar, NTT DATA will share practical case studies to demonstrate how the EAP can assist the MES, and provide a clearer understanding of the benefits that smart manufacturing can achieve in the industry.